Knife Steel Classification & Overview

Knife steel is fundamentally divided into five different categories:- Carbon Steel (C-Steel)

- non-stainless / rust-prone

- unalloyed & low alloy steel

-

Semi-Stainless Knife Steel (High Alloy Carbon Steel)

- rust-prone / semi-stainless

- Alloying elements are present in higher proportions than in conventional carbon steel

-

Stainless Knife Steel (High Alloy Chromium Steel)

- stainless

- High chromium content for corrosion resistance

-

PM Knife Steel (Powder Metallurgy Steel)

- Most modern manufacturing method

- The microstructure is finer with the same alloy, resulting in better performance

- Can be stainless or non-stainless

- Damascus Steel

- A special form

- Depending on the composition, it falls into one of the above four categories

It should be noted that technically speaking, "stainless" does not actually exist, but this term is commonly used for easy classification.

Among high alloy chromium steels, there are also differences in the level of corrosion resistance.

In the knife community, a steel is generally considered stainless if it does not rust under normal conditions (exposed to air, left in freshwater without drying).

For corrosion resistance in saltwater, elements such as nickel, molybdenum, and nitrogen are added and/or the chromium content is increased. Lowering the carbon content is also possible.

The Most Important Factors of a Knife

-

Knife Geometry | Tailored to the properties of the steel and intended use

- Blade grind | Flat, hollow, Scandi, convex, etc.

- Edge angle

- Blade thickness

- Material thickness at the edge (also known as the "bevel")

- Proper heat treatment / hardening | Also matched to the knife geometry & application area

- Correct processing | To avoid warping and loss of hardness

- Hardness (HRC) | Edge retention, cutting edge stability

- Toughness | Fracture resistance, impact toughness, or resistance to chipping

- Steel alloy | Chosen for its properties, workability & intended use

- Corrosion resistance & maintenance requirements

What Does Sharpness Mean? A Look at Razor-Sharp Knives

The term "razor sharp" is interpreted differently. A knife can shave even at a 3000 grit finish, but with a 12000 grit, it achieves a much higher quality of shave.

In everyday language, a knife is often called "sharp" once it has been sharpened to about K1000 grit. For high-quality knives, true sharpness according to our standard only begins at around K3000 grit. Further refinement can be achieved by polishing and stropping with leather and diamond paste or sharpening stones up to K10000 for even greater sharpness.

For razors, a sharpness level of 12000 grit is optimal, as high sharpness is essential for a comfortable shave. In the kitchen or for hunting knives, such a fine finish is not always necessary. The effort required for this level of sharpening is rarely justified here. In practice, knives are often sharpened to 2000 or 3000 grit and then stropped with leather—often with polishing compound—if needed.

Which Steel is Suitable for a Knife?

First of all, the higher the alloy content, target hardness, and required properties, the tighter the tolerances become in heat treatment and machining. It is therefore crucial that the knifemaker can reliably control the chosen steel in their own process. A well-understood, seemingly “simpler” steel is in practice often the better choice than a theoretically superior steel that is not used to its full potential.

Forging Steel / Carbon Steel

When forging a knife, carbon steel is usually used, since stainless or alloyed steels require much more effort and precise temperature control during the forging process. Stainless steel cannot be fire-welded over an open flame; for stainless Damascus, for example, vacuum welding methods are required.

For robust knives such as outdoor or hunting knives, steels with around 0.5% to 0.8% carbon are often selected. For kitchen knives, steels starting from 0.8% carbon are typically used.High Alloy Carbon Steel

Usually processed via stock removal, these steels are often highly wear-resistant and are considered semi-stainless.

High Alloy Chromium Steel

Sometimes referred to as high carbon steel, which is metallurgically correct since chromium steel also contains carbon. However, in the knife making community, this would cause confusion, so we generally refer to it as stainless knife steel. Mainly used in the stock removal process.

Powder Metallurgy Steel (PM Steel)

PM steel is produced by a modern process, enabling alloys that would not be possible with conventional melting technology.

The process also allows for finer microstructures compared to conventionally melted steels with the same alloy.

Example: ATS34 vs. RWL34—same alloy, but RWL34 is tougher, finer-grained, and has higher edge stability.

However, this does not mean these are the finest steels; there are also conventionally melted steels (NitroV, AEB-L, LC 200N) that are finer than many PM steels.

With PM steel, it's mainly about combining properties or achieving extreme wear resistance.

Damascus Steel

Historically, Damascus steel was considered the best, as it was produced by the best smiths.

The folding technique increased quality back then, mainly because steel production was not as advanced.

Today, where steel quality from leading steel mills is excellent, forging can only improve it to a limited extent.

If the forging process is not mastered, the steel can actually be negatively affected.

Forging offers advantages in shaping, especially regarding material savings for full-tang and semi-tang knives.

Today, Damascus is mainly used for its aesthetics.

Is Stainless Knife Steel Less Sharp Than Carbon Steel?

If you use the right stainless steel and all parameters are optimized, the sharpness is identical.

For example:

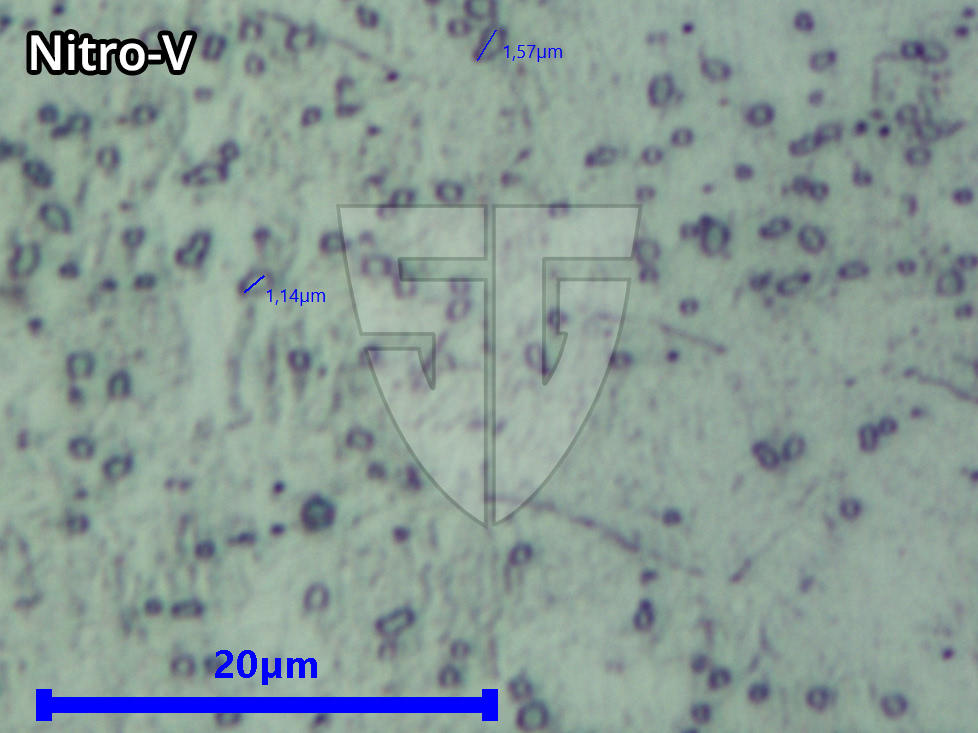

Nitro-V exhibits extremely fine grain among stainless steels, with carbide size about 1 to 2 microns (1–2 µm).

A good working hardness here is about 62 HRC.

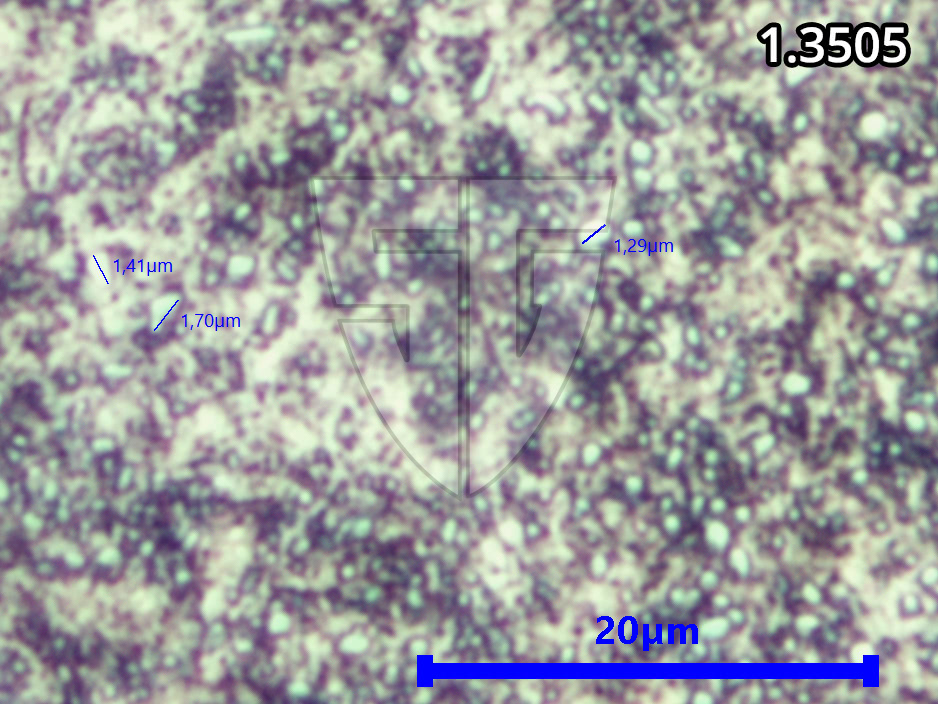

Fine-grained bearing steel 1.3505 also has carbides about 1 to 2 microns (1–2 µm) with a working hardness of 61 HRC.

Since both are very fine-grained and have high hardness & toughness, both can be ground to extremely thin edges.

So what distinguishes these two steels, apart from Nitro-V being stainless and 1.3505 being non-stainless?

- Nitro-V tends to hold its edge slightly longer due to an increased number of fine chromium carbides, which are harder than iron carbide

- Bearing steel is somewhat easier and faster to sharpen

- Heat treatment is considerably more complex and demanding with Nitro-V

- 1.3505 is excellent for forging and fire welding

Microscopic Structure Image

Nitro-V, hardened to 62 HRC

1.3505 Bearing Steel, hardened to 61 HRC

Note: Tungsten-alloyed carbon steels often have a much coarser structure (and higher edge retention due to tungsten carbide), so the right carbon steel must be chosen for the finest edge. The same applies to stainless and semi-stainless knife steels; there are real "carbide monsters" among them (where sharpness is not as high), which should not be ground as finely, since their strengths lie in other geometries.

Unfortunately, there's a common misconception that stainless steels are generally less sharp. As explained above, this is not necessarily related to corrosion resistance. Many end users are only familiar with stainless blades at 50–56 HRC or can't get highly alloyed steels sharp, which may be where this belief comes from.

Among knife makers, the biggest challenge is the demanding heat treatment and more difficult processing of stainless knife steels. Especially with PM steel, the difference is enormous compared to conventional carbon steel. Many fail to carry out proper heat treatment or achieve the desired sharpness, and so chromium steel is often (incorrectly) labeled as not sharp.