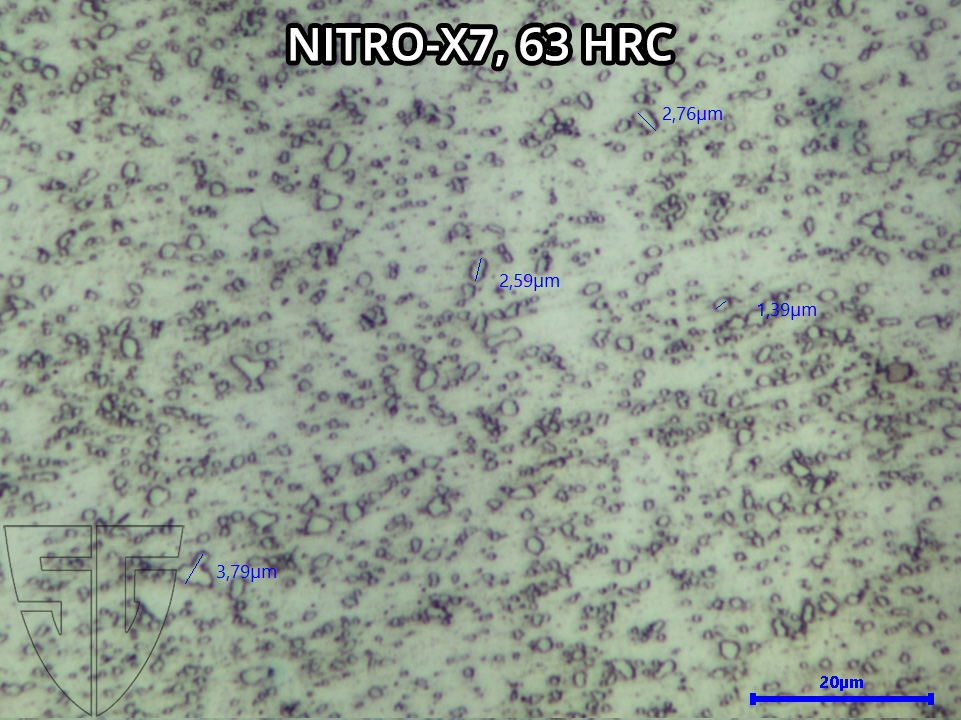

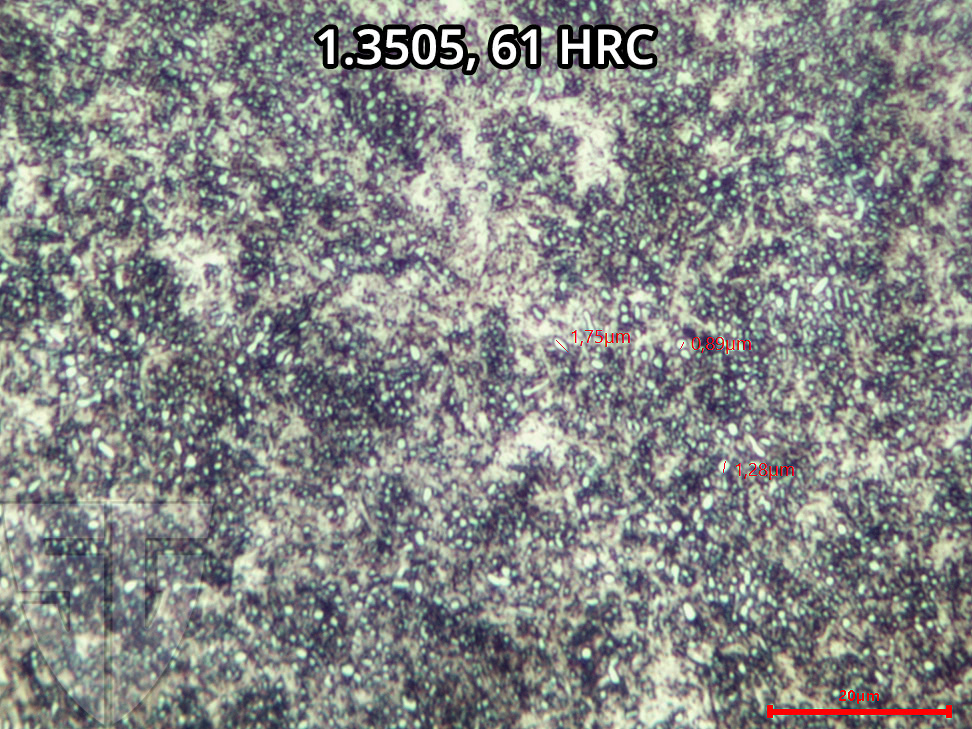

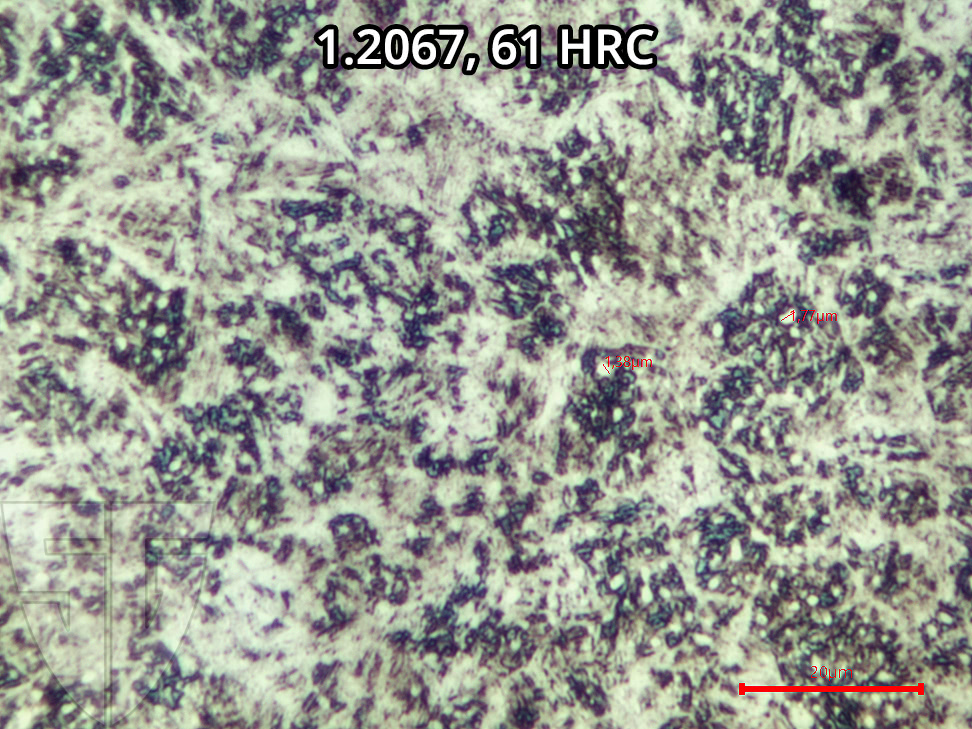

Many people assess knife steel primarily by hardness (HRC)—but hardness is not all the same. A high HRC value alone says little about the real-world usability of a blade. The decisive factor is the microstructure that develops during heat treatment. Two identical knives made from the same steel with similar HRC values can differ significantly in sharpenability, edge retention, and toughness, depending on how the steel was hardened.

The aim of our hardening process is a microstructure optimized for each steel with:

- fine, homogeneous microstructure

- controlled retained austenite content through optimal hardening parameters

- balanced ratio between hardness and toughness

Even if the HRC value looks good, problems can arise if heat treatment is not carried out correctly:

- Overheating: produces coarse microstructure and brittleness

-

Soak time: too long or too short; must be adjusted to knife geometry

- Can lead to grain growth or incomplete transformation

-

Temperature control: not kept consistently precise

- Causes different hardness zones and can introduce stresses in the blade material

-

Retained austenite: Many high-alloy steels require cryogenic treatment, otherwise too much retained austenite remains, especially when high hardness is desired. Without this step, the hardening parameters must be adjusted, which means the full potential of the steel cannot be achieved.

- Alternatively, high tempering (secondary hardness peak) can be used to reduce retained austenite, but at the expense of corrosion resistance and often also toughness

-

Effective oxidation protection: such as protective gas or vacuum is often neglected for high-alloy steels

- Critical for stainless or high-alloy steels, as these tend to decarburize, leading to loss of hardness and reduced wear resistance or a soft edge

- Ensures clean & uniform surfaces

This can result in a blade that does not become truly sharp or dulls quickly, despite good steel selection. It can also increase the risk of breakage.

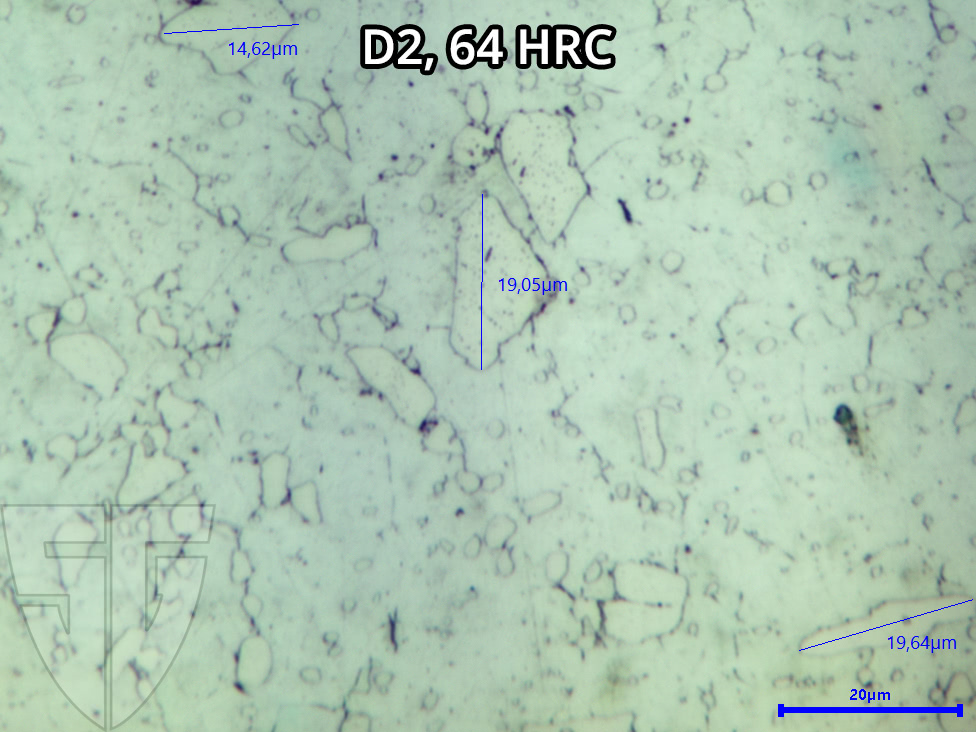

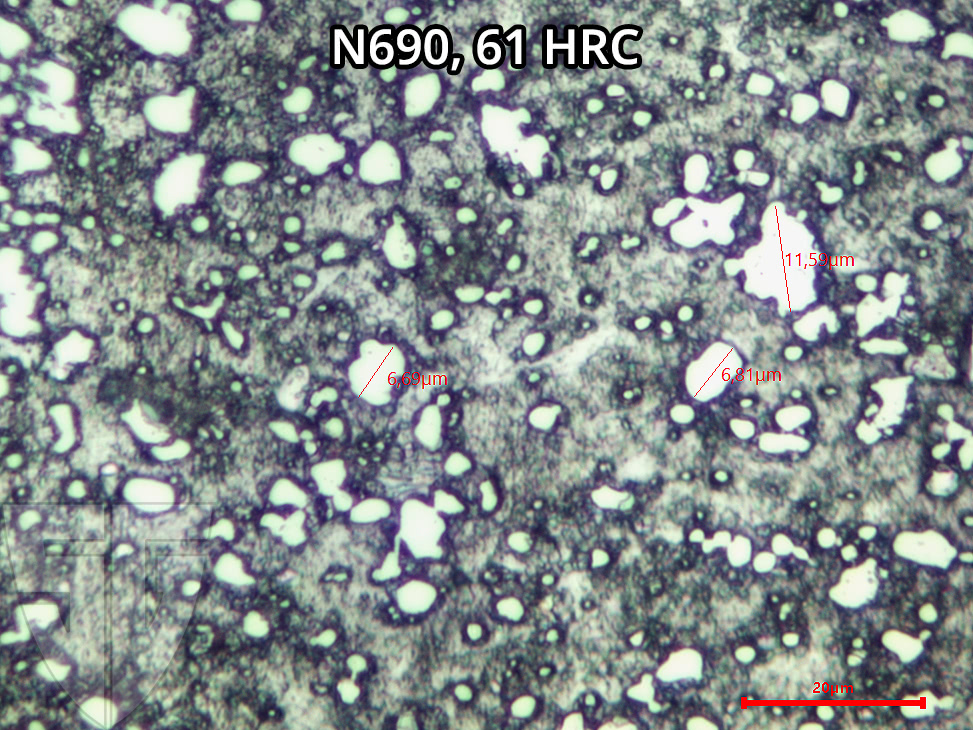

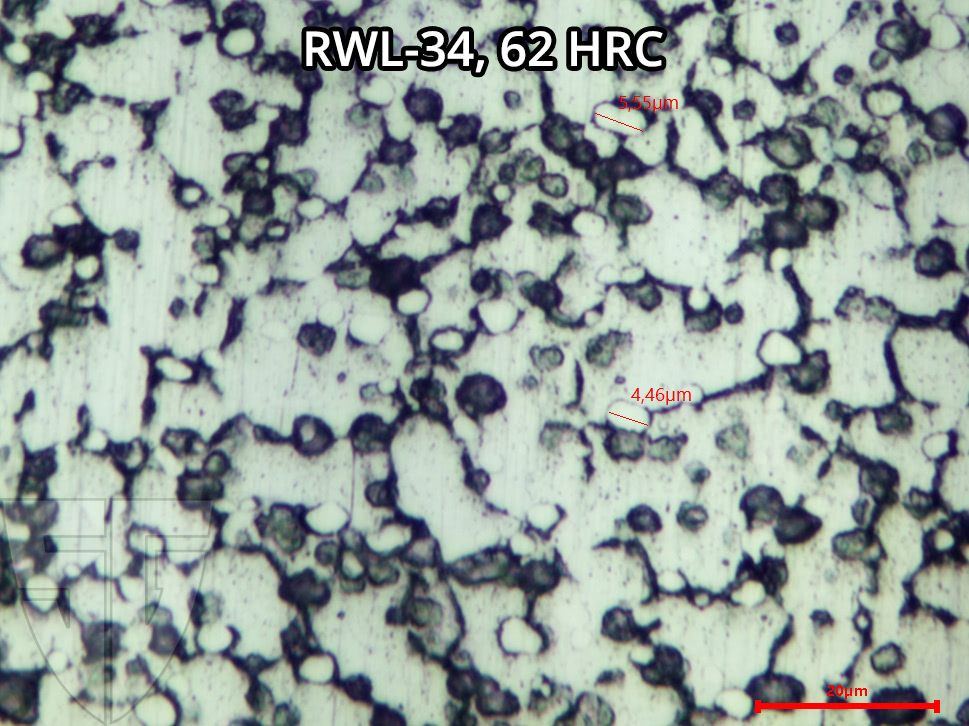

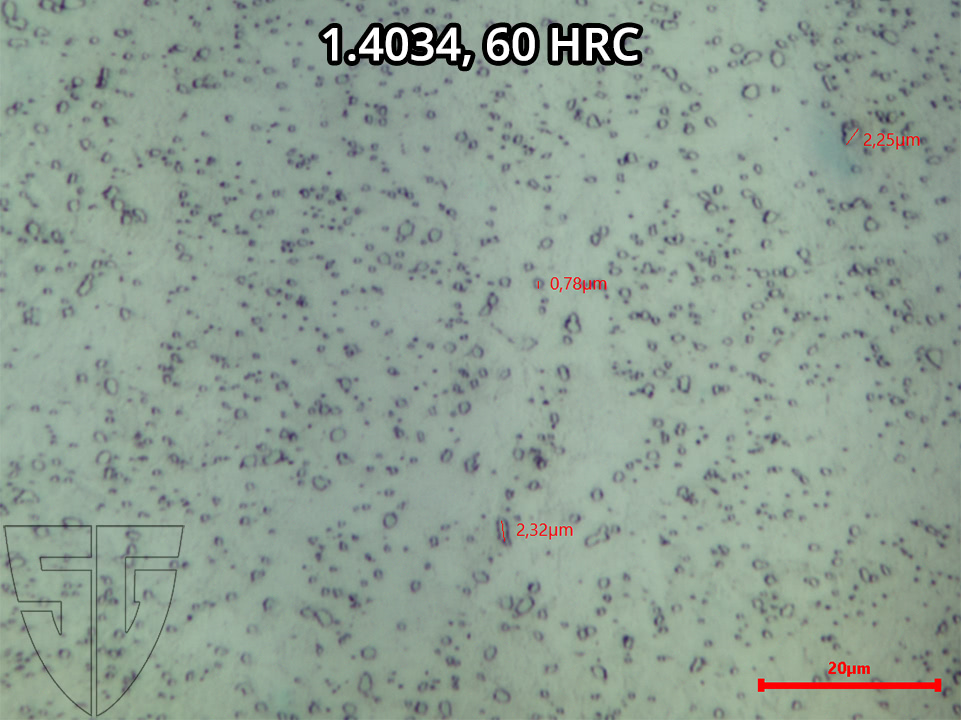

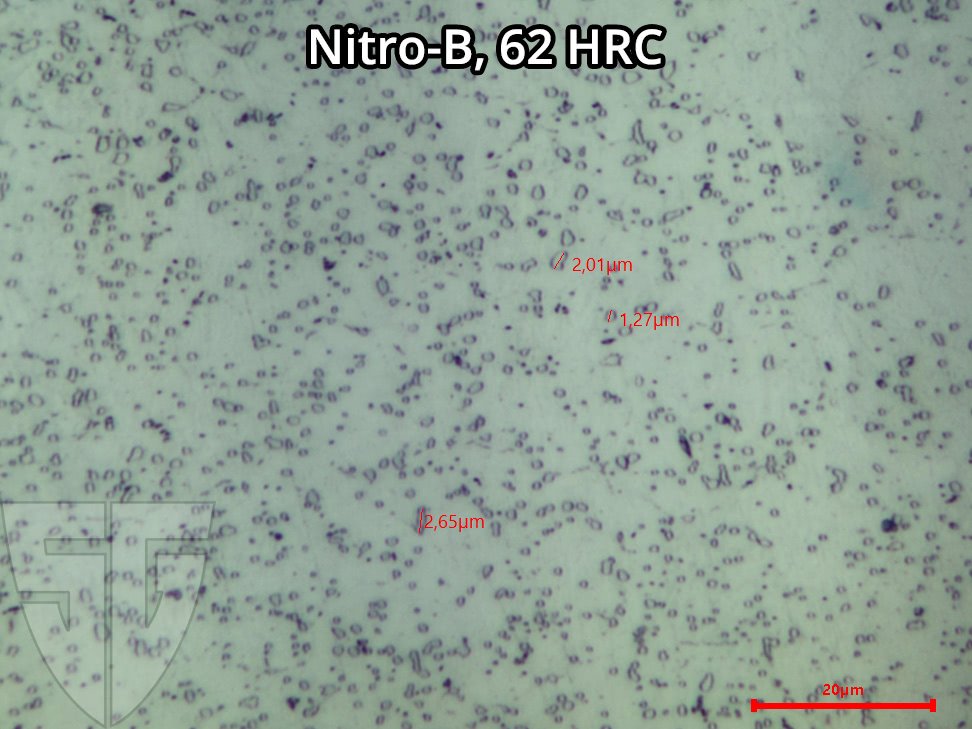

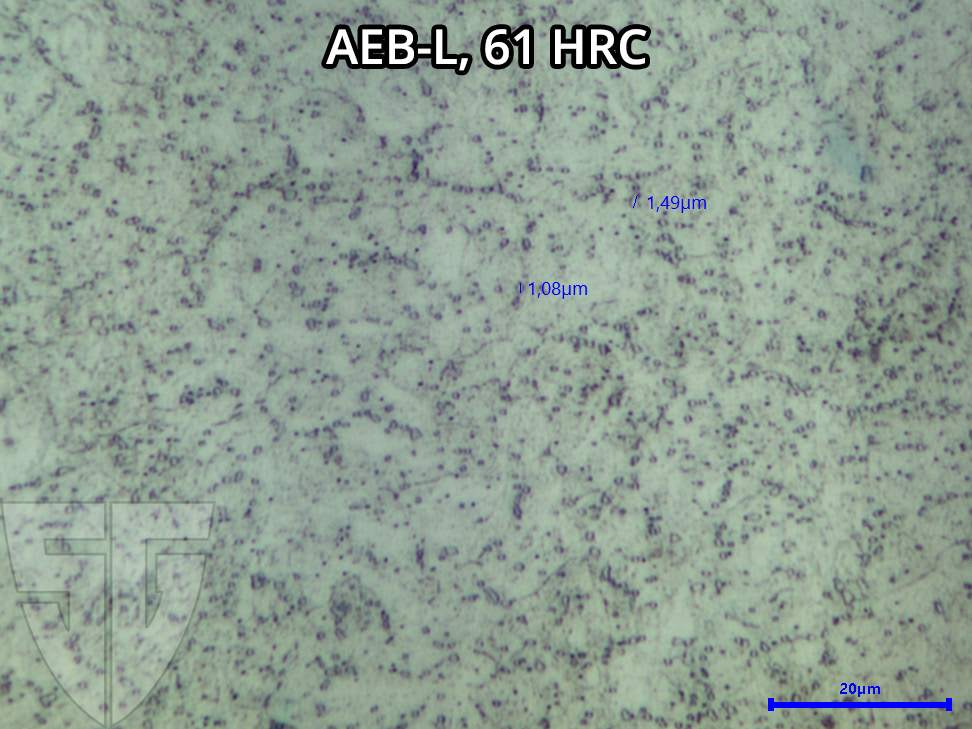

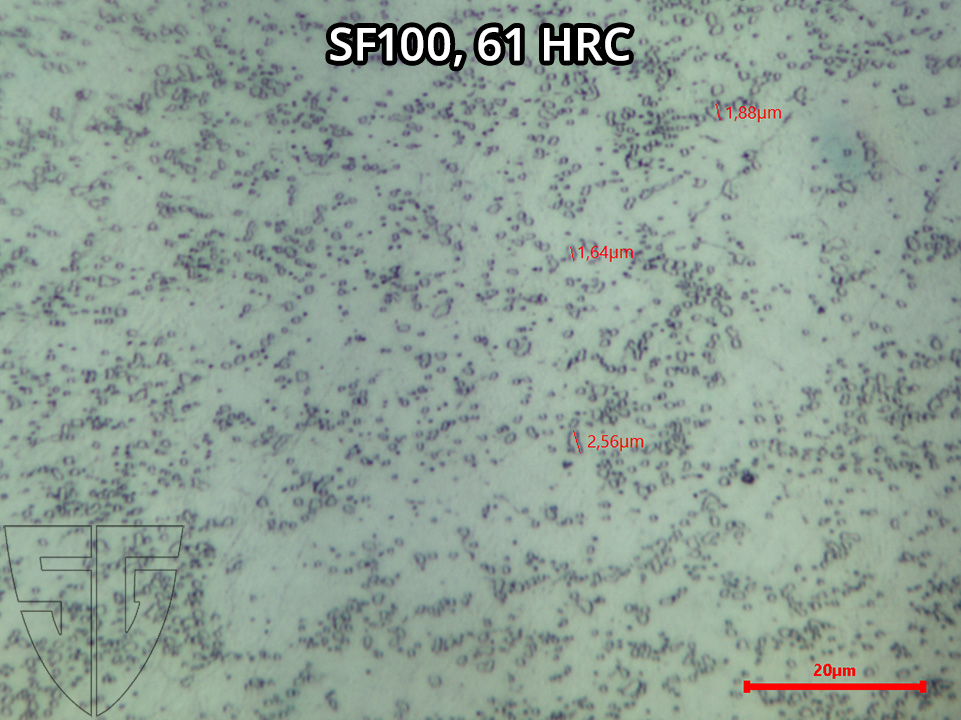

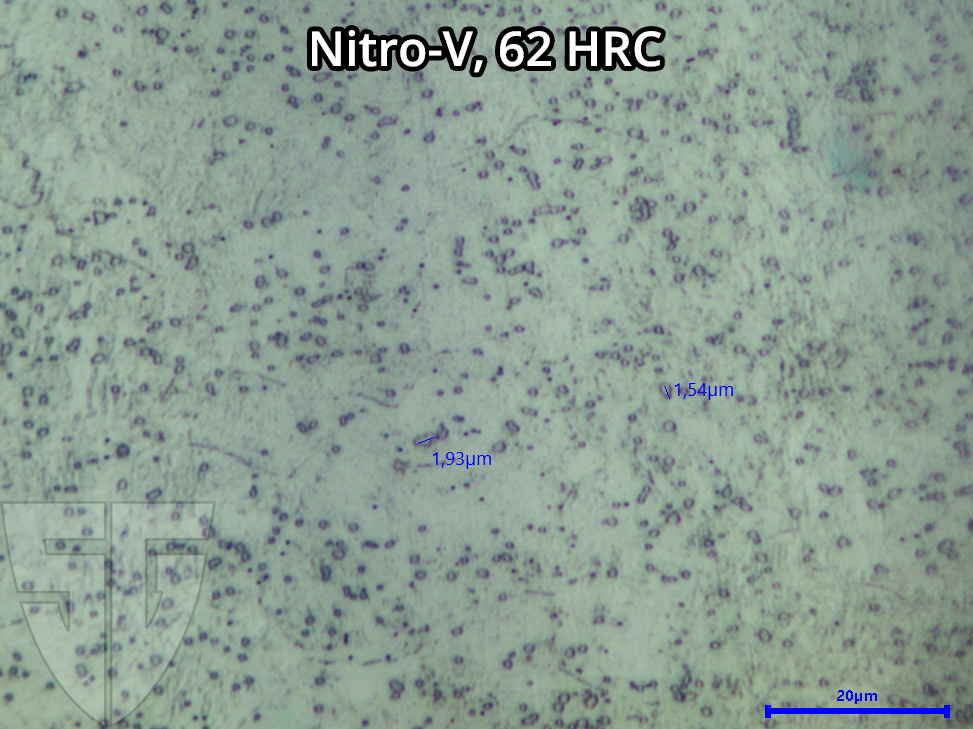

We verify our heat treatment using microscopic microstructure images in our own small laboratory, taken under identical conditions. This reveals how strongly heat treatment parameters influence carbide structure and homogeneity, and why hardness alone is not a sufficient quality criterion.