|

EUR

19,50

/per pcs.

incl. 20% VAT. |

In stock.

| If an order includes hardening, we will wait to ship until the blade(s) have arrived and have been hardened. |

The material thickness at the cutting edge should be at least 0,6mm for carbon steel, and 0,4mm for stainless steel.

For laminated steel, grind down only up to 1mm.

Please clearly mark each blade (indicate steel type with a waterproof marker on the tang/handle) and additionally enclose a note with: address, order number, steel type, and which blade, if any, should be measured for individual HRC testing or the hardness certificate.

Note on the measuring point: For a correct Rockwell test, the measuring point must be metallically clean and flat. Therefore, we prepare the surface if necessary in the measuring area at the tang/handle transition by lightly removing scale or oxide layer. Measurements are only possible if the handle/tang provides enough area (min. 10x10mm) and does not have an excessively irregular thickness (e.g., with a forged tang).

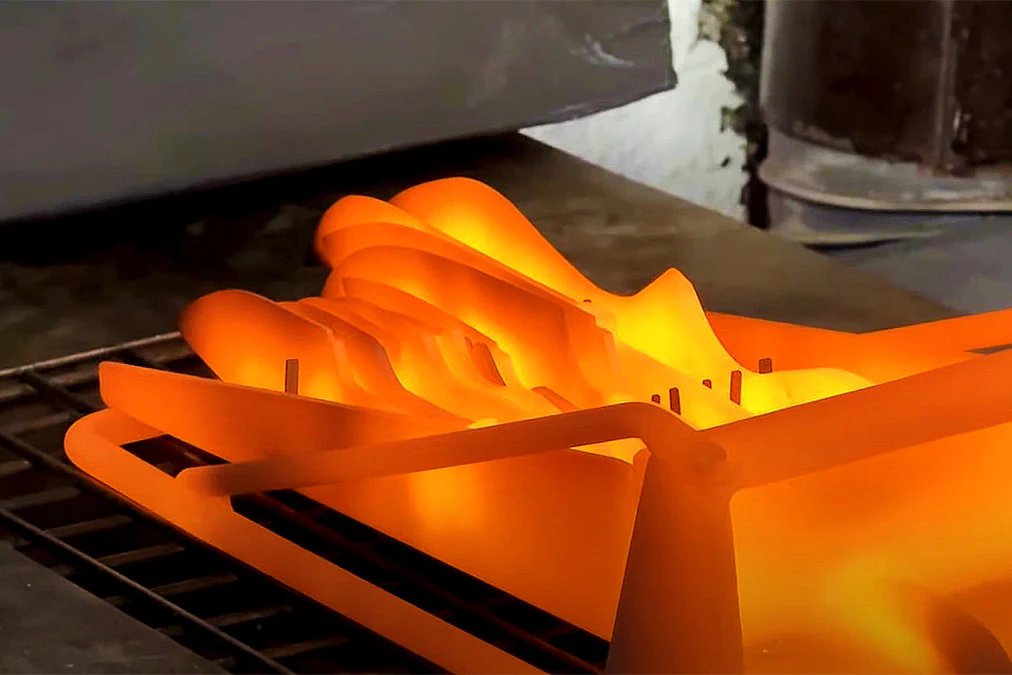

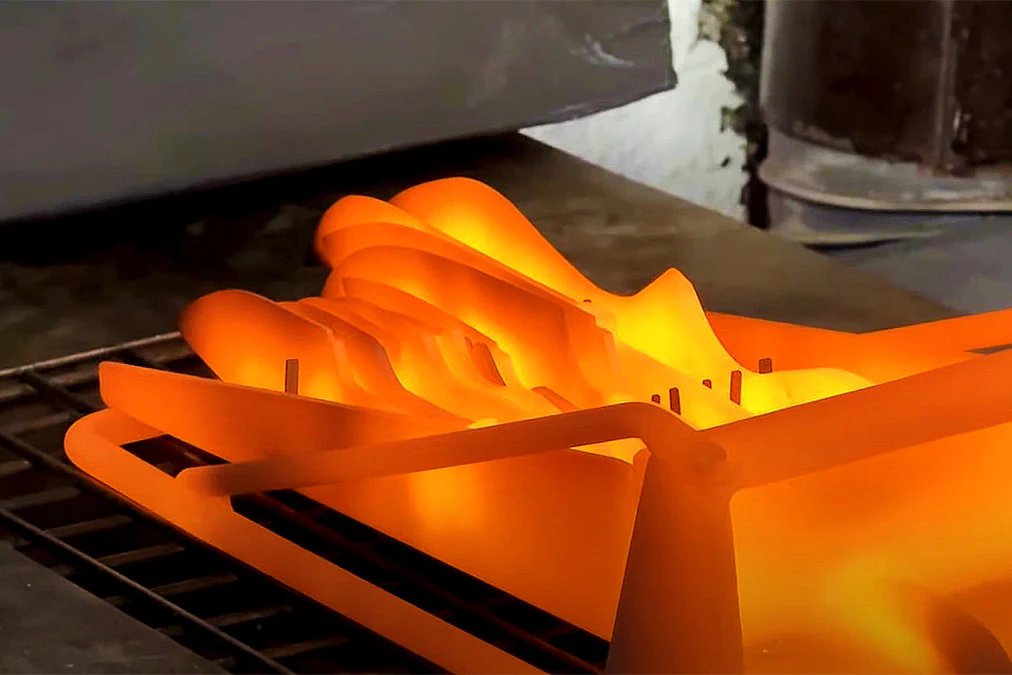

Our heat treatment for knife blades up to 33 cm includes:

Carbon steel is hardened in the furnace without scale protection.

Stainless steel & PM steel are protected in an argon atmosphere and air-quenched, resulting in only a very thin oxide layer.

Rusting laminated steel (carbon steel) is not cryogenically treated due to the increased risk of cracking.

During hardening, blades may warp; we attempt to straighten them, but in extremely rare cases the blade may break. We do not provide any warranty for warping or breakage during hardening.

For more information, please visit our website.