|

EUR

13,50

/per piece

incl. 20% VAT. |

In stock.

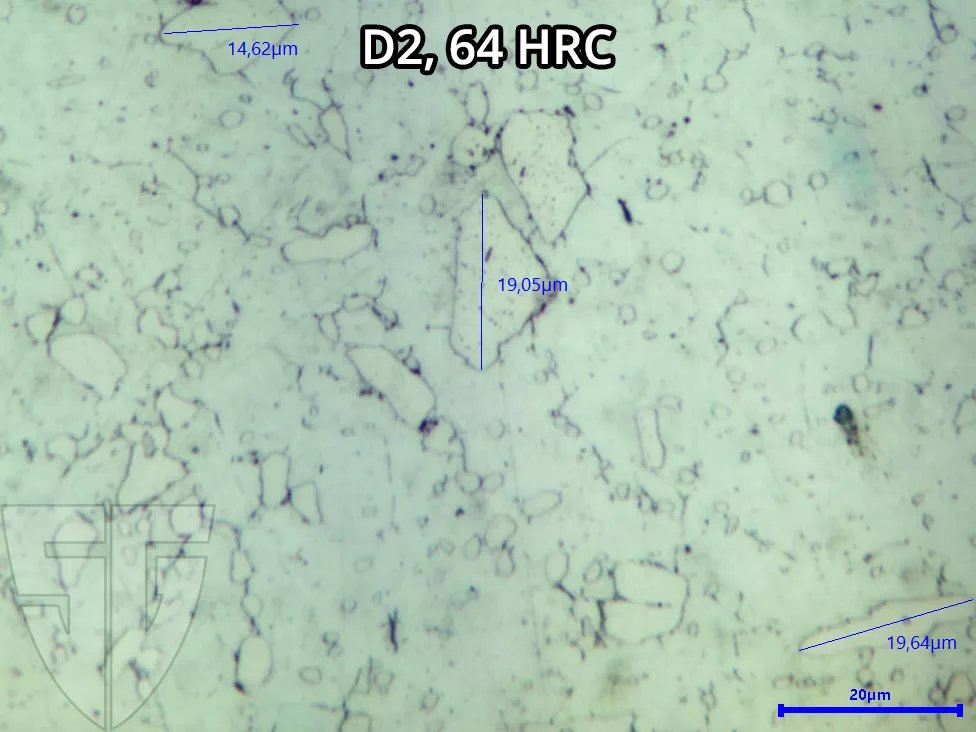

| We recommend D2 steel for more robust blade geometries, as it tends to chip due to the larger carbides if the blade is ground too thin. The edge should be at least 0,4 mm thick. |

The blade steel Böhler K110 / 1.2379 or AISI D2 steel is a ledeburitic 12% chromium steel. Especially suitable for air hardening.

Properties

Recommended applications

Chemical composition

C: 1,56% | Si: 0,32% | Mn: 0,36% | Cr: 11,24% | Mo: 0,72% | V: 0,72%

Our "D2 / Böhler K110 or 1.2379" heat treatment recommendation:

Hardening:

Annealing: Hold for 2 hours at 825°C, then cool slowly.

Stress relieving: Hold for 2 hours at 650°C, then allow to cool slowly.

Forging: 1050°C to 850°C, slow cooling in the furnace

Edges may be sharp – risk of cuts! Always wear appropriate protective equipment when working: gloves, safety glasses, and a dust mask. Store in a dry place to prevent corrosion. Not suitable for children – not a toy!