The BladeMark Press Standard is a stamp press designed for cold stamping of soft-annealed steel.

- For professional marking of custom-made knives

- Consistent depth thanks to ball-bearing press technology

- Allows positioning at rest for a clean result

- Compact design (Dimensions approx.: Width: 30mm, Height: 85mm, Depth: 50mm)

- Works on carbon steel, stainless steel, as well as PM steel grades and non-ferrous metals

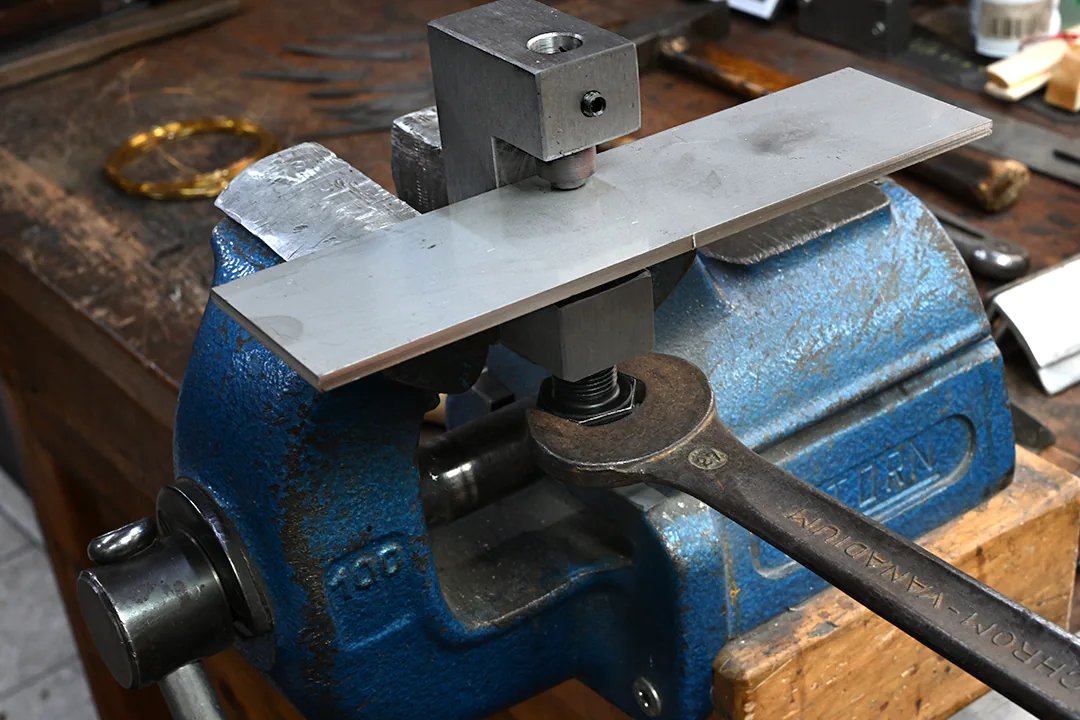

- A wrench & vise are required

- Made in Austria

We have relied on this system for years, as it has proven to be the best for us. It allows for much easier positioning compared to hydraulic presses and ensures a clean result, as the stamp is pressed evenly. Now we want to offer this system as a solution to all knife makers.

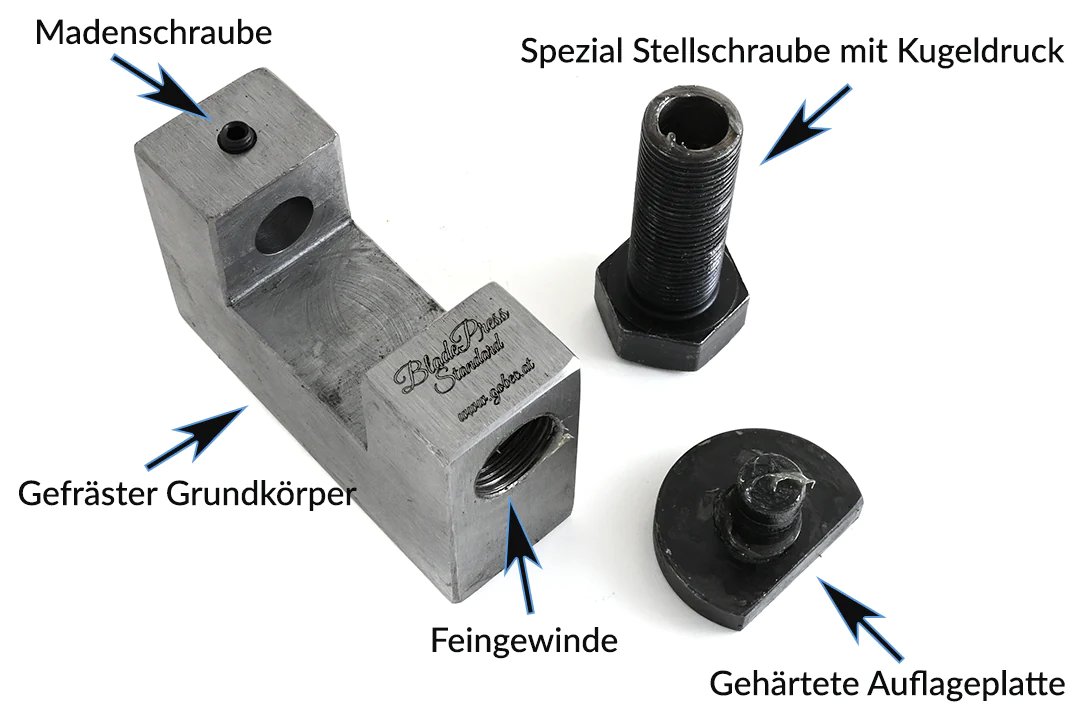

The press consists of the following parts (delivered pre-assembled):

- Milled base body with stamp hole and fine thread hole for the special screw

- Set screw (for securing the stamp)

- Hardened support plate

- Special adjustment screw with ball pressure

Instructions

- Clamp the stamp straight and secure it moderately with the set screw.

- Clamp the stamp press firmly in the vise.

- Place the blade blank between the support plate and the stamp and tighten the screw hand-tight.

- If necessary, the screw can now be gently loosened, the blank precisely positioned, and tightened again by hand.

- Hold the blank to prevent slipping and turn the screw a quarter turn with the wrench. The blank can now be released and another quarter turn applied with both hands.

- The screw can now be loosened; if necessary, hold the blank in place while doing so.

Ideally, perform a test stamping on scrap material; for thin sheet such as 2,5mm and below, do not press the stamp too deep.

Only suitable for the ricasso or flat surfaces, not suitable for angled surfaces.

The press is delivered without stamp and without wrench or vise.

Dimensions: W: 30mm, H: 85mm, D: 50mm